Series

|

N/A

D1834 Series: Potted-In Panel Insert

|

Type

|

N/A

Potted-In

|

Potted-In Style

|

N/A

Potted-In

|

Material

|

N/A

Carbon Steel per ASTM-A108, ASTM-A576, or material composition per AIR4127, Ultimate Tensile Stregth 85 KSI minimum

|

Standard Finish

|

N/A

Cadmium Plate per AMS-QQ-P-416, Class 2, Type II

|

Thru-Bolt Type

|

N/A

C'Sunk Thru Hole

|

|

L - Min. Length of Insert1

|

N/A

0.312 in

|

A - Diameter +.000 -.010

|

N/A

0.685 in

|

B - Body Diameter

|

N/A

0.370 in

|

C - C'Sink Diameter x 100º

|

N/A

0.507 in

|

|

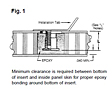

D - Clearance Hole2

|

N/A

0.256-0.263 in

|

Head Thickness

|

N/A

0.060 in

|

J

|

N/A

0.467 in

|

K - Min

|

N/A

0.360 in

|

Installation Hole Size

|

N/A

0.686-0.691 in

|

Installation Tab No.

|

N/A

T6

|

Aligning Tool

|

N/A

G6

|

J - Tool

|

N/A

0.467 in

|

A - Tool

|

N/A

0.900 in

|